fluorescent colors ( 3D COLOUR )

Price 7999.0 INR/ Kilograms

fluorescent colors ( 3D COLOUR ) Specification

- Place of Origin

- India

- Type

- fluorescent colors

- Style

- Organic Pigment

- Physical State

- Liquid

- Purity(%)

- 99%

- Application

- Industrial

fluorescent colors ( 3D COLOUR ) Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Supply Ability

- 1000 Kilograms Per Month

- Delivery Time

- 7 Days

About fluorescent colors ( 3D COLOUR )

High-Purity Fluorescent Pigments

Featuring 99% purity, these organic fluorescent colors offer outstanding intensity and clarity. The superior formulation ensures that each application delivers consistent, bright hues essential for industrial-grade finishes. Their high chromatic strength makes them ideal for end-products demanding vivid appearance and longevity.

Versatile Industrial Applications

Suitable for both liquid and powder-based systems, our pigments integrate seamlessly into a broad spectrum of industrial uses. From plastics and coatings to specialty paints, these pigments enhance visibility and aesthetics. Manufactured in India, they comply with rigorous quality standards, fitting diverse industrial needs.

Reliable Indian Manufacturer and Supplier

As a leading supplier in India, we guarantee a steady supply of fluorescent colors tailored for industrial needs. Our products undergo strict quality control to ensure reliability, safety, and vibrant results. With an efficient distribution network, clients across various industries receive prompt and dependable service.

FAQs of fluorescent colors ( 3D COLOUR ):

Q: How are fluorescent colors (3D COLOUR) used in industrial applications?

A: Fluorescent colors (3D COLOUR) are typically added as pigments in processes such as paint manufacturing, plastic molding, and textile printing. Their unique formulation allows seamless integration, resulting in vibrant and highly visible end products.Q: What benefits do organic fluorescent pigments offer over conventional pigments?

A: Organic fluorescent pigments deliver bolder, more luminous colors compared to traditional pigments. Their high visibility and brightness improve product appeal, while their organic composition ensures safer handling and eco-friendliness in industrial settings.Q: When should I choose fluorescent colors in liquid versus powder form?

A: Liquid fluorescent colors are ideal for applications requiring fast dispersion or where water-based systems are used. Powder forms are preferred where higher pigment loadings are necessary or for incorporation into dry-mix processes.Q: Where are these fluorescent pigments manufactured and supplied from?

A: These pigments are manufactured and supplied from India, where state-of-the-art facilities uphold stringent quality standards to meet the demands of industrial clients domestically and internationally.Q: What is the process for incorporating fluorescent pigments into industrial products?

A: Fluorescent pigments are blended into base materialslike plastic resins or paint basesduring manufacturing. Proper mixing and dispersion techniques are critical to achieving uniform coloration and optimal fluorescence.Q: What industrial sectors commonly utilize fluorescent colors (3D COLOUR)?

A: Common sectors include plastics, paints, coatings, inks, textiles, and automotive industries. The pigments high visibility and durability make them suitable for products needing standout appearance and enhanced safety features.Q: What are the main benefits of using 99% pure fluorescent pigments in industrial processes?

A: Using pigments of 99% purity ensures superior brightness, consistency, and color integrity in finished goods. This level of purity also contributes to reliable performance, improved quality, and reduced risk of impurities affecting manufacturing outcomes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pigment Powder Category

Turquoise Blue Pigment Powder

Price 65 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Purity(%) : High

Physical State : Powder

Type : Turquoise Blue Pigment Powder

Style : Organic Pigment

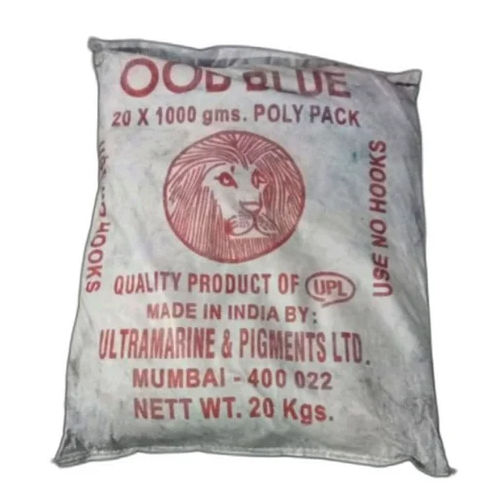

OOB Ultra Marine Blue Pigments

Price 20 INR / Kilograms

Minimum Order Quantity : 20 Kilograms

Purity(%) : High

Physical State : Powder

Type : OOB Ultra Marine Blue Pigments

Style : Organic Pigment

Fluroscent Orange Pigment Powder

Price 61 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Purity(%) : High

Physical State : Powder

Type : Fluroscent Orange Pigment Powder

Pink Pigment Powder

Price 56 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Purity(%) : High

Physical State : Powder

Type : Pink Pigment Powder

Style : Organic Pigment

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS